Preshaped, 4D microcoils for personalized endovascular embolization

A research team led by Prof. Xu Tiantian from the Shenzhen Institute of Advanced Technology (SIAT) of the Chinese Academy of Sciences, and the collaborators, introduced 4D ultraviolet (UV)-curable organogel microcoils with adaptive shapes for personalized embolization. The study was published in Advanced Materials.

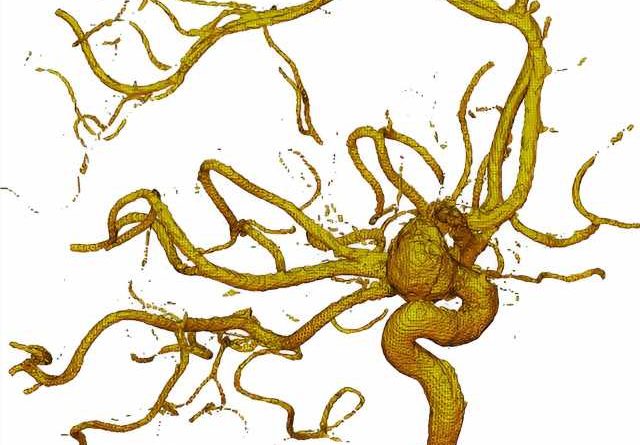

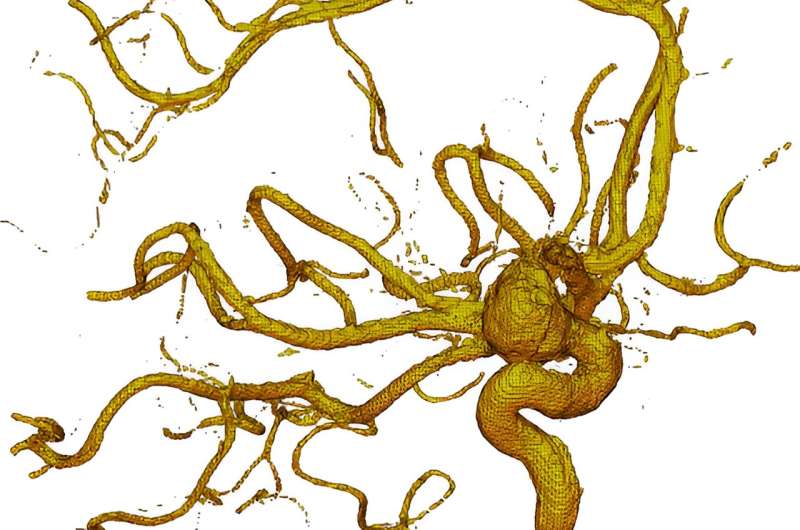

Endovascular embolization using microcoils proves to be an effective technique for treating artery aneurysms, a concealed and potentially fatal vascular disease. However, microcoils with fixed designs face challenges in adapting to various aneurysm types.

In this study, the researchers presented a photocurable ultratough shape memory organogel with a rapid curing time of only two seconds. They utilized this material to craft personalized 4D microcoils with a wire diameter as small as 0.3 mm, closely resembling the wire diameter of metallic microcoils.

In comparison to natural hydrogels with high water content and photocurable hydrogels, the proposed organogel addresses issues of fragility and brittleness, demonstrating an improved modulus/strength which increases from kilopascal to megapascal levels (511.63 MPa). This enhancement reduces the risk of microcoil fractures during embolization. Moreover, the organogel exhibits a fast body-temperature-triggered shape memory ability, enabling the 4D microcoil’s applicability in vivo.

The 4D microcoils were deployed into rabbits, and they effectively obstructed blood flow in different aneurysms. Neoendothelial cells and collagen fibers grew snugly on the microcoil surface, indicating complete aneurysm recovery.

“Our 4D organogel microcoil holds the potential for clinical translation in humans. Its adaptable shape for different aneurysms could resolve the issues associated with current microcoils having fixed shapes,” said Prof. Xu.

More information:

Shu Wang et al, Preshaped 4D Photocurable Ultratough Organogel Microcoils for Personalized Endovascular Embolization, Advanced Materials (2023). DOI: 10.1002/adma.202308130

Journal information:

Advanced Materials

Source: Read Full Article