Research team develops new technology for robotic prosthetic leg control

A research team led by Professor Sang-hoon Lee at the Department of Robotics and Mechatronics Engineering, Daegu Gyeongbuk Institute of Science and Technology has successfully developed an imperceptive surface electromyography (sEMG) sensor. The sensor is crucial in allowing lower limb amputees to control robotic prosthetic legs as they want and is expected to contribute greatly to rehabilitation and a better quality of life.

With the recent rise in lifestyle diseases such as diabetes, there is a rapidly growing number of additional lower limb amputees. The permanent effects of lower limb amputation are not only physical disability but also psychological disability. To tackle this problem, bionic lower limb technology has been developed in recent years to replace a lost leg with robotic prosthetics.

The most important thing in developing robotic prosthetic legs is to stably implement the lower limb function as intended by amputees, and in order to do so, the ability to rapidly and accurately acquire the amputees’ biological signals is required. The most suitable method is to use non-invasive sEMG sensors; however, these sensors are difficult to use in practice.

The sensor must be located inside the silicone liner of the socket to record electromyographic signals. However, the silicone liner is very narrow, it creates a humid environment, and it is impacted by the socket, which is subject to strong dynamic movements due to the weight of a robotic prosthetic leg. This makes it impossible to stably record muscles’ biological signals for a prolonged period of time without damage to the sensor itself.

In this context, a research team led by Professor Sang-hoon Lee at DGIST developed an imperceptive sEMG sensor, a biointerface formed through a microelectromechanical system. The study is published in the journal npj Flexible Electronics.

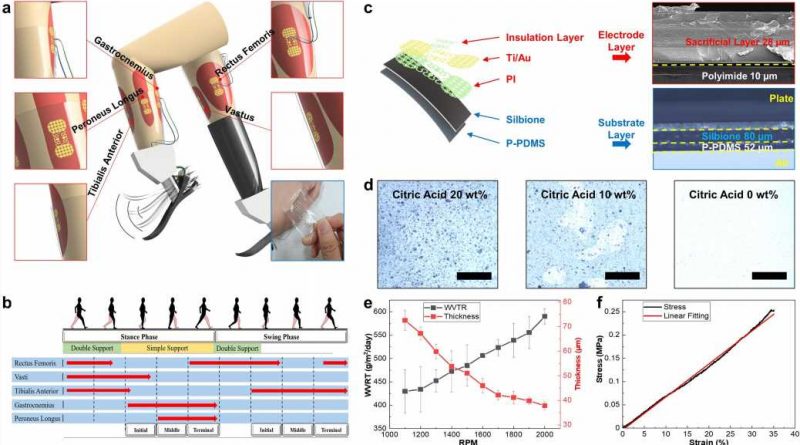

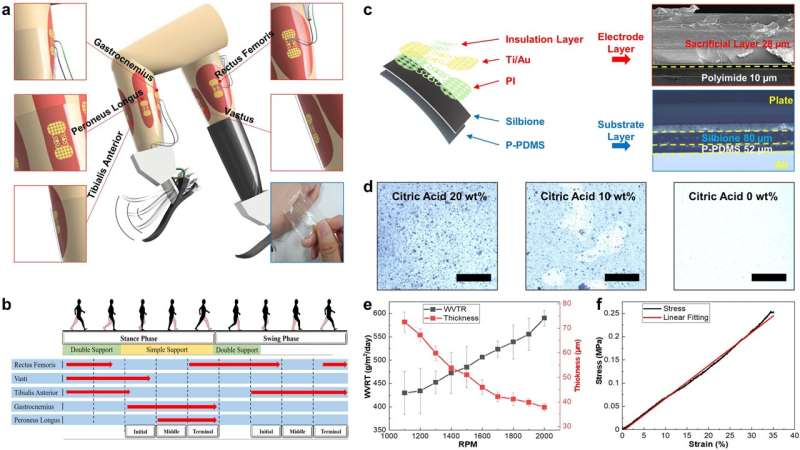

The imperceptive sEMG sensor developed by the research team mimics a serpentine structure to provide flexibility and elasticity while achieving breathability and adhesion. Hence, the sensor can be applied to various amputated parts of the body and can be used repeatedly over an extended period of time. Furthermore, combined with a wireless module, the sensor obtains real-time signals generated when amputees walk with robotic prosthetic limbs, sockets and silicone liners.

To verify the sensor’s function, the research team attached the imperceptive sEMG sensor to a lower limb amputee and evaluated the sensor’s function by recording the amputee’s muscle signals. The results demonstrated that the sensor successfully acquired high-quality real-time muscle signals of the amputee walking in various environments (on flat ground, up and down slopes, and on stairs) and transmitted the signals wirelessly to assist the amputee in walking, as verified from the motion analysis sensor embedded in the robotic prosthetic leg.

Furthermore, by analyzing muscle signals generated from plantar flexion and dorsiflexion in amputees, the research team confirmed that the selective signal acquisition performance of the imperceptive sEMG sensor is better than that of other commercial sensors. In this regard, the research team expects the sensor to be applied across various wearable technologies, in addition to precise control of robotic prosthetic legs and hands based on bio-signals.

Professor Lee said, “Although there are more amputees than we think in Korea and around the world, there are many restrictions on daily activities and living because prosthetic legs that can be controlled as the wearer intends are not available. Based on the results of this research, we will continue to further research and ultimately develop bionic limbs which can implement sensory and motor functions, just like that of human limbs, to help amputees enjoy all activities of daily living.”

More information:

Jaeu Park et al, Imperceptive and reusable dermal surface EMG for lower extremity neuro-prosthetic control and clinical assessment, npj Flexible Electronics (2023). DOI: 10.1038/s41528-023-00282-z

Journal information:

npj Flexible Electronics

Source: Read Full Article